Do you have flexible, positive-coated photo base material (Flexpcb) which can also be soldered?

It is possible in principle, to coat Kapton (or other films) with our photoresist. But, because the photoresist is NOT flexible, handling (exposure, development, etching) is easily generating cracks.

Unfortunately, this is almost normal, even if our competitors conceal this fact to create fast business.

If you really want to have flex material coated, then you should think about NEGATIVE PHOTO COATING. Negative dry resist is flexible and not kink-sensitive.

One more question: Can you also work with so called RIGID-FLEXIBLE or semiflexible pcbs?

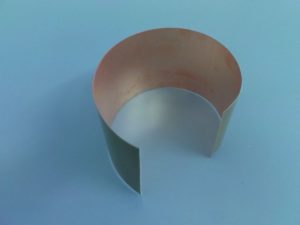

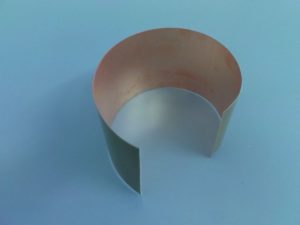

What is the bending radius you need? Background: We have also FR4 with a thickness of 0.125 mm carrier and 35μm copper layer (single or double sided) in stock. We sell this for the same price as 0.5 mm FR4 in size 510x1150mm. Cutting service is possible.

With these thin FR4 FR4 you have normal (solder) properties at an extremely small bending radius (see photo). Perhaps that would help you already?

Contact us today by email on

info@hitec-ams.com to get our experts help

Source: Bungard website