Customer Service

-

- AR

- /

- EN

-

Part of the NEW NovaPlaceTM Series, the L-NP00 is an entry level, low-cost turnkey automatic pick and place system that can be put in production right out of the box. Once a specific PCB is programmed, the machine automatically picks up each component from its designated feeder or tray, centers the part and moves to the placement location, and accurately places the part. The feeders automatically position the next component for pick-up.

| Max board size | 13.5" x 22" (343 x 560mm) |

| Smallest component capability | 0402 Components |

| Largest component size | 1.378" (35mm) square body |

| Placement accuracy | ±0.004" |

| Max placement rate | 2100 cph |

| Typical verifiable placement rate | 1000-1800 cph |

| Fine pitch capability | 25 mil |

| Max travel area | 22" (X axis) x 22" (Y axis) (560 x 560mm) |

| Overall dimensions | 40" x 42" x 25"h (1016 x 1067 x 635 mm) |

| Max no. of feeders (8mm tape) | -0- |

| Max no. of feeders with L-BF-12 bank feeders | -0- |

| Tape feeders | -0- (Cut tape only) |

| Vibratory Feeders | -0- |

| Matrix Tray Feeders | with Board/Matrix tray holders |

| Centering | Centering Fingers |

| Vision system | Color CCD card camera |

| Dispenser Option | Time & pressure, clean dry air @ 80 psi required |

The L-NP32 NovaPlaceTM pick and place system is a complete, low-cost turnkey automatic pick and place machine that can be put in production right out of the box. Once a specific PCB is programmed, the machine automatically picks up each component from its designated feeder or tray, centers the part and moves to the placement location, and accurately places the part. The feeders automatically position the next component for pick-up.

| Max board size | 13.5" x 22" (343 x 560mm) |

| Smallest component capability | 0402 Components |

| Largest component size | 1.378" (35mm) square body |

| Placement accuracy | ±0.004" |

| Max placement rate | 2100 cph |

| Typical verifiable placement rate | 1000-1800 cph |

| Fine pitch capability | 25 mil |

| Max travel area | 22" (X axis) x 22" (Y axis) (560 x 560mm) |

| Overall dimensions | 40" x 42" x 25" h (1016 x 1067 x 635 mm) |

| Max no. of feeders (8mm tape) | 32 |

| Max no. of feeders with L-GB-12 bank feeders | 48 |

| Tape feeders | 8, 12, 16, 24, 32, and 44mm (Electrical) |

| Vibratory Feeders | Loose, tube, stick (frequency & amplitude control) |

| Matrix Tray Feeders | With Board/Matrix tray holders |

| Centering | Centering Fingers |

| Vision system | Color CCD card camera |

| Dispenser Option | Time & pressure, clean dry air @ 80 psi required |

The HA06 is a solder oven for SMD component with the use of lead free paste. The oven is work-ing with full convection forced air during the preheat stage. When the reflow stage is entered the heating will be done by hot air and quartz lamps. The lamps are needed to get a short ramp speed. Once the refl ow set point is reached the lamp power will be reduced to a minimum. At this point 85% of the heating is caused by forced hot air. This unique feature makes the oven suitable for solder big SMD components and/or components with pads under their casing while using lead free paste. With good maintenance and proper use the oven will serve your solder needs for a long time with high quality solder results. Features

The HotAir3000 is a stylish, practical reflow oven for manufacturingand reworking of SMT products. The oven has a large display. The intuitive menu navigation is controlled by a membrane keyboard. The product uses highly efficient infrared heating elements and has several thermocouple temperature gauges. Due to this and the precise evaluation in the microprocessor, the temperature curve of the reflow process is highly accurate and the temperature in the respective reflow sections very uniform. With the HotAir3000 all common alloys can be processed. The oven has an automatic error detection with alarm. This product has a variety of applications such as reflow soldering, repairing, drying and so on. It is suitable for SMT small series, for research and development of electronic products, school, education and study. The operating system software is in English. The stove is well insulated by a special aluminum silicate cotton, which reduces energy consumption, protects the circuit and allows optimal operation and keeps the temperature in the furnace constant.

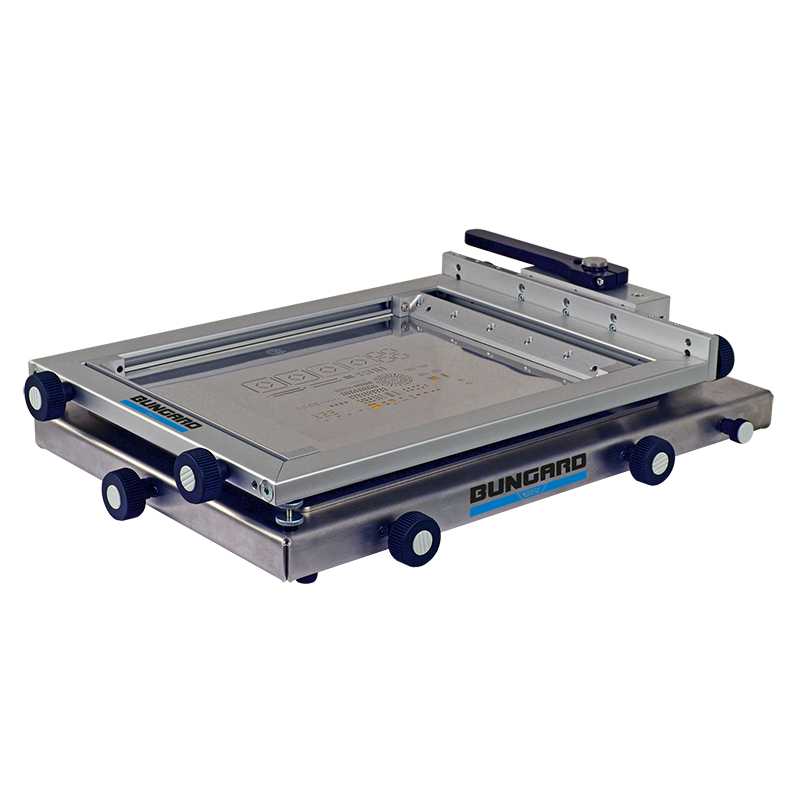

The stencil printer PrintStar 3000 manual printing machine with high precision is mainly designed for requirements of single or double-sided circuit board solder cream or red glue printing. The working platform is processed by cellular positioning hole with high-quality aluminum and its pedestal is welded by thick steel plate with steadiness and durability. Its characteristics are as follows: ● Circuit board adopts positioning needle, fixed rod and fixed plate for positioning, which can ensure convenient positioning and accuracy of repeated operation. ● Make ready mode is made through stencil's movement and combined with fine adjustment and correction of X, Y axis in printing platform, which is convenient and quick. ● Stencil stent uses spiral bearing and height can be adjusted up and down, which is convenient to control PCB's thickness and volume of printing cream. ● Printing plates are fixed by four rotary knobs with platen and it is quick and strong.

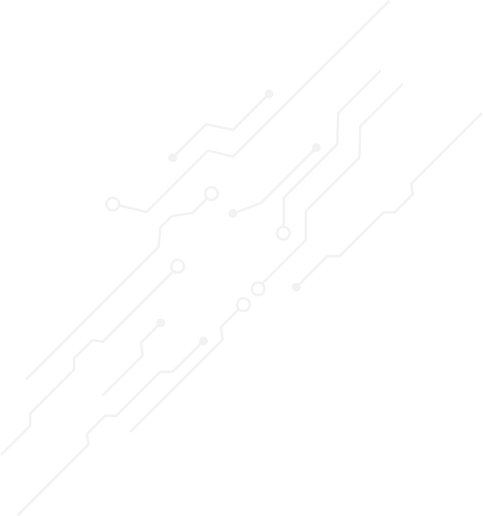

Manipulator for the production of prototypes and small series. The patent-registered Pick & Place head enables the comfortable handling of SMD-components. The modular-built system can be confi gurated for every use. It realizes the complete process - starting by dispensing of solder paste or glue up to assembling different component

Manipulator for the production of prototypes and small series. The patented Pick & Place head enables easy handling of SMD components. The modular system can be configured for any application. The system realizes the entire process from applying the solder paste or glue to assembling the various components.